News

Representation for PRIMIX in Colombia

Recently, Provetecmar S.A. has become the representative of PRIMIX in Colombia. We are very pleased with this expansion of our network and the great growth in the Spanish-speaking areas.

Provetecmar S...

New representation for PRIMIX in Spain

The PRIMIX network continues to grow. We are very pleased that Raimaber Fluid Tech has become our distributor and partner in Spain. The company has been a supplier of well-known brands of industrial p...

The PRIMIX network continues to grow. We are very pleased that Raimaber Fluid Tech has become our distributor and partner in Spain. The company has been a supplier of well-known brands of industrial p...

Lloyd's Award for PRIMIX - 25 years Quality Management certified

PRIMIX has received an extraordinary 25-year Quality Management Excellence Award from Lloyd’s

Read More

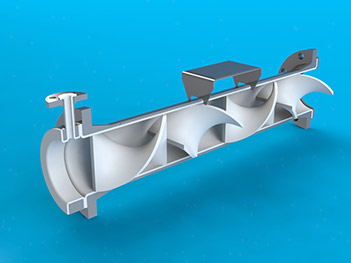

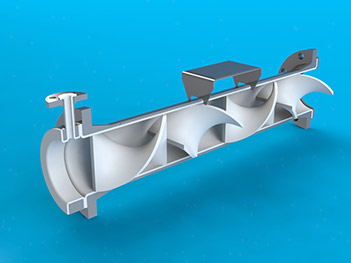

How does a static mixer work?

This news article explains the operating principle of the static mixer through a number of illustrative examples. Want to know more about how static mixers work, what they can be used for and the bene...

This news article explains the operating principle of the static mixer through a number of illustrative examples. Want to know more about how static mixers work, what they can be used for and the bene...

ISO9001:2015 self-evident?

Is a transition to ISO9001:2015 self-evident? For PRIMIX it certainly is. PRIMIX recently went through the transition process for the transition from ISO9001:2008 to ISO9001:2015. It also renewed its ...

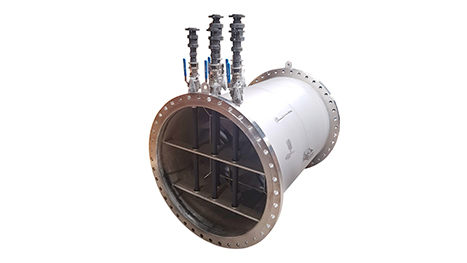

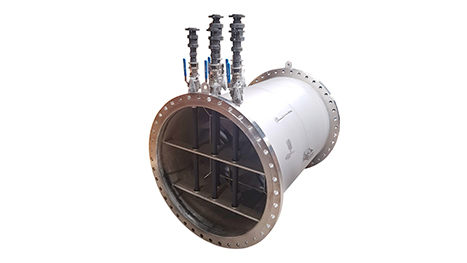

TLT and PRIMIX - specialist static mixers for the steel industry

As part of the HS Group, TLT (India) integrates specialist Primix static mixers in its installations for use in the steel industry, where blast furnace gases are mixed in large quantities in a very ho...

As part of the HS Group, TLT (India) integrates specialist Primix static mixers in its installations for use in the steel industry, where blast furnace gases are mixed in large quantities in a very ho...

PRIMIX product information now also in Spanish

Due to a sharp increase in demand for the Primix static mixers from, among others, Middle and South America, Primix has expanded the website to include the Spanish language as of April 2018. This simp...

Due to a sharp increase in demand for the Primix static mixers from, among others, Middle and South America, Primix has expanded the website to include the Spanish language as of April 2018. This simp...

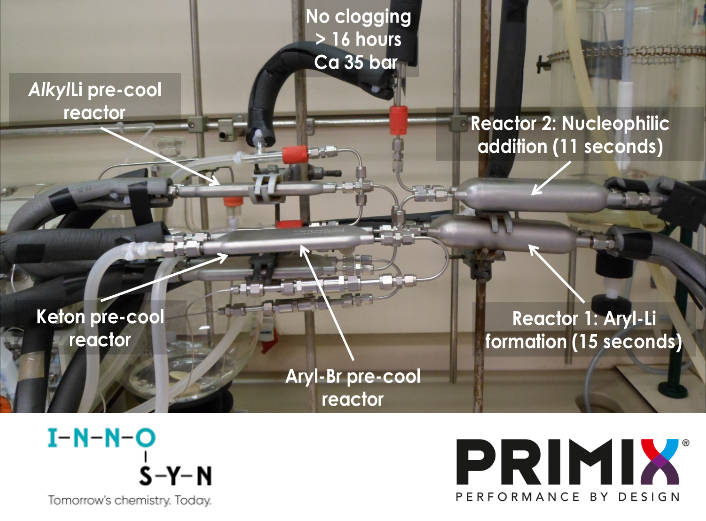

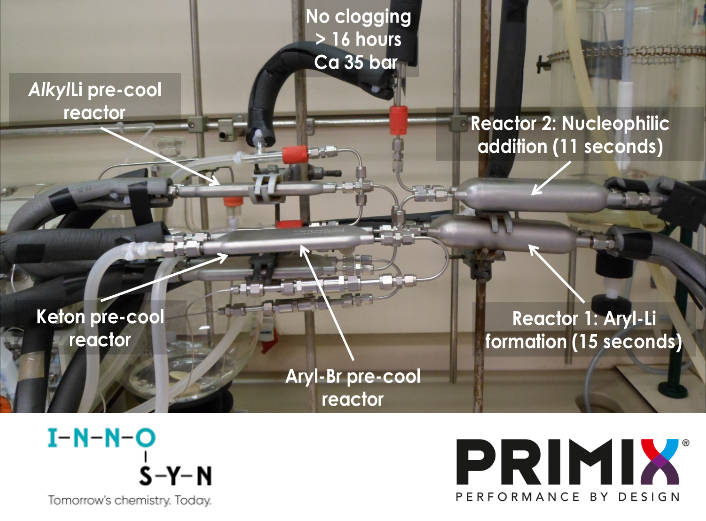

Boosting a trend – flow chemistry optimization in microreactors

This article is a joint publication of InnoSyn and Primix realized by R. Reintjens, M. Rijkers and R.J. Wakkers.

This article is a joint publication of InnoSyn and Primix realized by R. Reintjens, M. Rijkers and R.J. Wakkers.

Flow chemistry and microreactor technology finds their way more and more in commerciali...

Mixing of first-class drinking water

PRIMIX recently delivered one of the largest fully stainless steel static mixers in its history. The static mixer is installed in the Choa Chu Kang Waterworks (CCKWW) in Singapore and has a diameter o...

PRIMIX recently delivered one of the largest fully stainless steel static mixers in its history. The static mixer is installed in the Choa Chu Kang Waterworks (CCKWW) in Singapore and has a diameter o...

Primix appoints a new representative for Mexico

PRIMIX is very pleased to welcome Cramix-Fluidmix Group (CFG) as their new exclusive distributor for Mexico. With a continuously growing network of distributors PRIMIX can now provide an even wider gl...

PRIMIX is very pleased to welcome Cramix-Fluidmix Group (CFG) as their new exclusive distributor for Mexico. With a continuously growing network of distributors PRIMIX can now provide an even wider gl...

PRIMIX heat exchangers deployed on large-scale

In cooperation with their German partner BE.ST GmbH, PRIMIX recently obtained a very large order for the supply of almost 200 mono tube heat exchangers that are going to be used in a production proces...

In cooperation with their German partner BE.ST GmbH, PRIMIX recently obtained a very large order for the supply of almost 200 mono tube heat exchangers that are going to be used in a production proces...

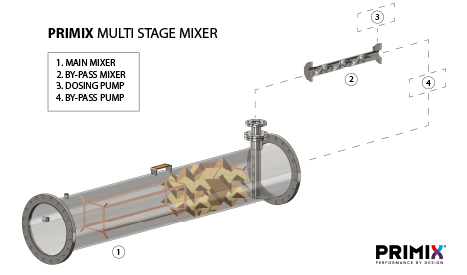

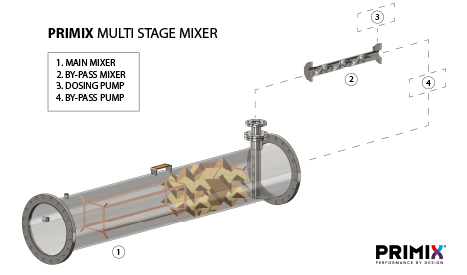

Advantages of a Multi-stage static mixer configuration

A multi-stage static mixer is the perfect solution when a small flow of additives needs to be mixed into a main flow that has a (very) large turn-down ratio. In practice this often means for example a...

A multi-stage static mixer is the perfect solution when a small flow of additives needs to be mixed into a main flow that has a (very) large turn-down ratio. In practice this often means for example a...

Additive injectors for static mixers in the water industry - a real necessity?

Static mixers are widely used in the water industry to mix specific chemicals in water, at water treatment and wastewater plants, in the production of drinking water and desalination plants. It is mai...

Static mixers are widely used in the water industry to mix specific chemicals in water, at water treatment and wastewater plants, in the production of drinking water and desalination plants. It is mai...

FPSO metering - An unstable gas composition is unacceptable

Before export gas is introduced into a pipe system, for further transport, several parameters of the gas are measured by, for example, ultrasonic measuring devices. Often condensate is also being admi...

Before export gas is introduced into a pipe system, for further transport, several parameters of the gas are measured by, for example, ultrasonic measuring devices. Often condensate is also being admi...

Static mixers and changes in the Pressure Equipment Directive ... when is CE applicable?

PRIMIX spends in its communication a lot of attention to new applications of static mixers and heat exchangers. This provides insights into solutions for special and challenging processes and enhances...

PRIMIX spends in its communication a lot of attention to new applications of static mixers and heat exchangers. This provides insights into solutions for special and challenging processes and enhances...

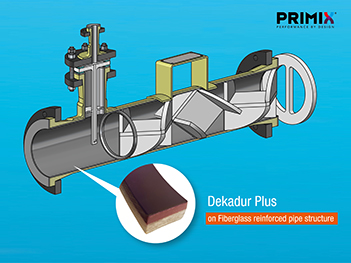

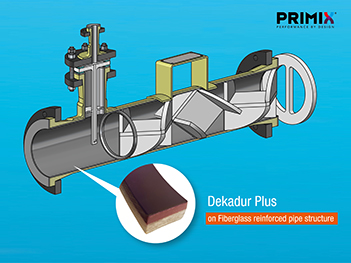

Static mixer liner provides high-temperature solution

The Rotterdam based AKZO Nobel factory recently started to operate a PRIMIX static mixer which features a Dekadur Plus liner. The lined mixer allows for continuous mixing of corrosive chemicals at hig...

The Rotterdam based AKZO Nobel factory recently started to operate a PRIMIX static mixer which features a Dekadur Plus liner. The lined mixer allows for continuous mixing of corrosive chemicals at hig...

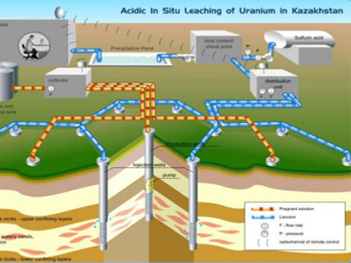

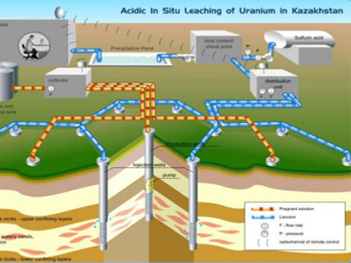

How static mixers contribute in uranium mining

One of the leading mining companies in Kazakhstan has awarded a 2-year contract for a large number of static mixers to PRIMIX. The contract was obtained by the local PRIMIX partner who is providing al...

One of the leading mining companies in Kazakhstan has awarded a 2-year contract for a large number of static mixers to PRIMIX. The contract was obtained by the local PRIMIX partner who is providing al...

DNV classification of static mixers for offshore applications

Process components on offshore installations for the extraction and production of oil, are subject to high standards. The PRIMIX static mixers are operated with great success in those installations an...

Process components on offshore installations for the extraction and production of oil, are subject to high standards. The PRIMIX static mixers are operated with great success in those installations an...

Primix appoints a new representative for the Nordic countries

With an ever-expanding network of distributors Christian Berner has been appointed as Primix's exclusive distributor for the Nordic countries.

With an ever-expanding network of distributors Christian Berner has been appointed as Primix's exclusive distributor for the Nordic countries.

Primix appoints a new representative for Oman

Abu Ilyas Trading LLC has been appointed as Primix's exclusive distributor for Oman.

Abu Ilyas Trading LLC has been appointed as Primix's exclusive distributor for Oman.

Smallest static mixer for Pilot Plants

PRIMIX has supplied one of its smallest static mixers to a system integrator in the petrochemical industry for use in a pilot plant.

PRIMIX has supplied one of its smallest static mixers to a system integrator in the petrochemical industry for use in a pilot plant.

Static mixer for safe dilution of sulfuric acid

There are many chemical processes in which concentrated sulfuric acid (H2SO4) must be diluted to the required concentration. Applications can be found in the chemical industry, in scrubbers, but also ...

There are many chemical processes in which concentrated sulfuric acid (H2SO4) must be diluted to the required concentration. Applications can be found in the chemical industry, in scrubbers, but also ...

Static mixers for biofuels

Due to rising fuel prices and more strict environmental rules, biofuels are increasingly popular. This increases the demand for equipment that can produce high-quality biofuels such as biodiesel.

Due to rising fuel prices and more strict environmental rules, biofuels are increasingly popular. This increases the demand for equipment that can produce high-quality biofuels such as biodiesel.Biodi...

PRIMIX acquires FPAL and JQS registration

Recently, PRIMIX has acquired an Achilles FPAL registration next to their JQS registration.

The JQS and FPAL registration are filled under registration number 300 072 376.

English

English  Deutsch

Deutsch  Español

Español  Français

Français  Nederlands

Nederlands