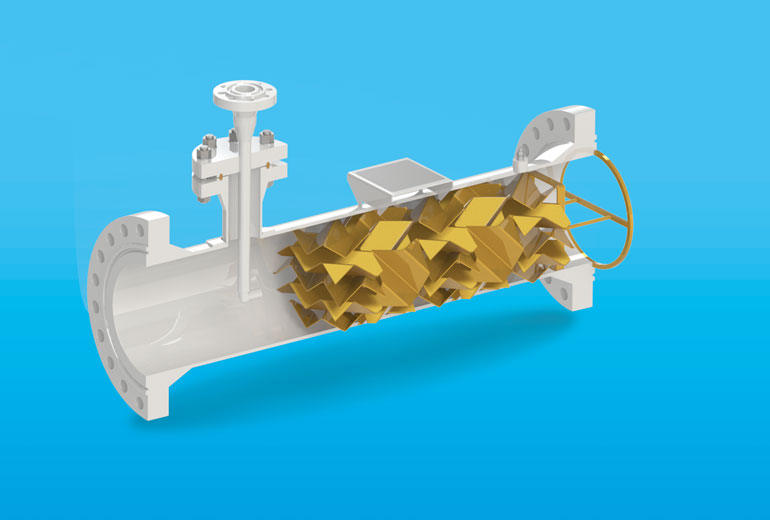

Static mixers for mineral extraction processes

We at PRIMIX believe that maximal and long lasting achievements during the process can only be realised by an appropriate design. In the design, we combine our extensive knowledge in the field of fluid dynamics with a meticulous way of working. All parameters and pre-conditions are considered before the design process is started. We think beyond existing paths and thus develop solutions for new applications and complex issues. Only when we are sure that all parameters are mapped, do we design the ideal mixer or heat exchanger for your process. The certification and classification are seen as an integral part of the design process. This results in components that deliver maximum performance during the process and also meet all certification and documentation requirements.

It’s all-in the design

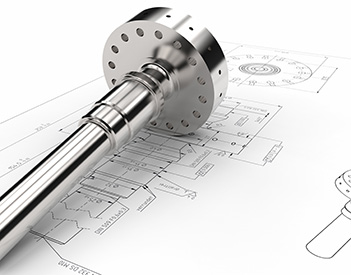

At PRIMIX design is more. It includes the engineering and thinking through the process with the client. Clearly defining the relevant parameters and where necessary daring to ask critical questions. This with the aim of obtaining maximum performance in the process . The intended design is entirely calculated in our own PRIMIX Dynamics software and afterwards is designed in SolidWorks® . The design instructions and calculations are based on strict criteria formulated in the current industrial design standards for high pressure devices. PRIMIX is also ISO-9001 certified.

Producing and supplying appropriate documentation - now and in the future

Producing and supplying appropriate documentation - now and in the future

Design also means certification and making sure the documentation is correct. It is also important to carefully file the detailed drawings and calculations so that in future the appropriate support can always be provided. During our after care we can adjust your mixers and heat exchangers with these accordingly, should any process adjustments be necessary.

The packaging is an important part of the delivery

The packaging is an important part of the delivery

At PRIMIX the client can be sure that all our products will arrive intact and in good condition. PRIMIX sets the highest standards for packaging, shipping and delivery; we are very careful about it and do not try to economise on packaging and delivery costs because we know that the packaging is the business card of our company; our clients see this first. We pack in strong cardboard boxes, pallets or specially designed export packaging for any given specific order. For this we cooperate with an internationally renowned packaging company. Wooden ISPM 15 (International Phytosanitary Measure 15) packaging suitable for air and/or sea freight to anywhere in the world, and also suitable for long-term storage, are also used. Via Track and Trace you can always follow the status of your delivery, fast and simply.

PRIMIX performance - more than just parameters

In our field of work it is always about the decimals. Not surprisingly, because accuracy regarding hygiene or homogenization in the food and chemical industries are crucial. All PRIMIX static mixers and heat exchangers are therefore delivered or tested with sensors and measuring equipment, making optimum monitoring and control possible. On line at any time. But ... not everything can be measured with instruments. For example the appearance or taste of food. Therefore PRIMIX always looks beyond the hard figures, does research and gives the right solutions for these dimensions too.

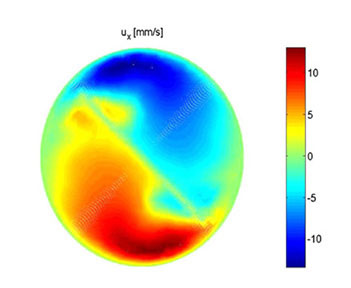

Copyright AIChEWe at PRIMIX find innovation an important part of our business. PRIMIX has partnerships with TU Delft and TU Eindhoven and several contacts with leading researchers in fluid dynamics. For issues that go back to the basics of flow patterns, answers and solutions can be found. Innovative methods are known that can actually make the flow patterns, that are created by the use of various types of mixing elements, visible. The test results of these measurement methods provide an insight into reality and are much more reliable than CFD techniques. The details that deliver practical measurements are particularly high; CFD can only approximate this because the amount of data that would be required to generate a comparable picture is enormous, which highly taxes the computer systems. The necessary limitations therefore produce a worse insight. PRIMIX's vision is that, in the case of complex flow problems, we can offer the client cooperation with R&D and have scientific research done on the basis of consultancy.

Copyright AIChEWe at PRIMIX find innovation an important part of our business. PRIMIX has partnerships with TU Delft and TU Eindhoven and several contacts with leading researchers in fluid dynamics. For issues that go back to the basics of flow patterns, answers and solutions can be found. Innovative methods are known that can actually make the flow patterns, that are created by the use of various types of mixing elements, visible. The test results of these measurement methods provide an insight into reality and are much more reliable than CFD techniques. The details that deliver practical measurements are particularly high; CFD can only approximate this because the amount of data that would be required to generate a comparable picture is enormous, which highly taxes the computer systems. The necessary limitations therefore produce a worse insight. PRIMIX's vision is that, in the case of complex flow problems, we can offer the client cooperation with R&D and have scientific research done on the basis of consultancy.

Example of research static mixers - paint industry

The craft industry, such as the paint industry, is often based on semi-batch processes that work with open vessels that are stirred by large stirrers. For cost reasons, mostly initiated by environmental improvement measures, it is often necessary to install expensive vapour extraction and processing plants. The transfer of this type of process to a continuous process can then be attractive because it greatly reduces the cost by using relatively small equipment. This kind of change over is often difficult because the exact mechanisms of the process are not known in detail.

Research is then necessary to record properly the parameters that determine the quality of the final product. Once this is known, the transition to continuous processing becomes possible. Where mixing plays a role, a static mixer is useful. Advantages of the static mixer are the absence of moving parts and shaft seals, very low maintenance, no leaks, a predictable homogeneity, low investment, and the ability to easily scale-up. It is expected that many industries will eventually make the change, and indeed, it has been happening for some time already.

PRIMIX is a global company that provides industrial solutions for mixing liquids and/or gases without rotating parts. Whether you are looking for a mixer solution for a large-scale chemical process, cooling food or mixing nutrients in horticulture, PRIMIX offers you the right solution.

PRIMIX has existed for over 30 years and has acquired a reputation as a worldwide supplier and manufacturer of high performance static mixers and heat exchangers. Because of numerous unique PRIMIX inventions our products are ideally suited for clean processes, CIP (Cleaning in Place), low and high temperatures and diverse viscosities. Any conceivable combination of gas and liquid and solids (powder and small particles) can be mixed, emulsified, suspended or subjected to a thermal treatment, with the static PRIMIX mixer.

Manufacturer with own production of static mixers and heat exchangers

PRIMIX as a manufacturer has their own production facilities, engineering, quality control and customer section. We also do R&D in cooperation with the TU in Eindhoven. Many of the mixers and heat exchangers are developed custom made on the basis of the client's process application. This is done with a lot of attention to detail by our well trained workforce.

Worldwide available

PRIMIX exports its own products around the world and works with representatives abroad. Wherever you are active in the world, PRIMIX offers a suitable solution for your process issues. In the development phase we are involved in factory design and often work closely with engineering firms. In a later phase, we assist where appropriate, with the installation of the systems.

Static mixer research & development

We at PRIMIX find innovation an important part of our business. PRIMIX has partnerships with TU Delft and TU Eindhoven and several contacts with leading researchers in fluid dynamics. For issues that go back to the basics of flow patterns, answers and solutions can be found. Innovative methods are known that can actually make the flow patterns, that are created by the use of various types of mixing elements, visible.

Design vision

We at PRIMIX believe that maximal and long lasting achievements during the process can only be realised by an appropriate design. In the design, we combine our extensive knowledge in the field of fluid dynamics with a meticulous way of working. All parameters and pre-conditions are considered before the design process is started.

PRIMIX advantages for you

Very efficient static mixers and heat exchangers that are connected 100% to the process

Energy saving and cost effective, durable and maintenance free technology

Partner for engineering firms and the industry with worldwide support

More than 30 years of experience and a great deal of knowledge of fluid dynamics

Mixer dimensioning and design with PRIMIX calculation software and 3D CAD-software

Full mechanical and performance guarantee

Single Source – In house engineering and (certified) product facility for fast and reliable delivery

State of the art R&D - with support from TU Delft and TU Eindhoven

Flexible organisation with short lines of communication

English

English  Deutsch

Deutsch  Español

Español  Français

Français  Nederlands

Nederlands