Sanitary static mixer

The PRIMIX sanitary static mixers are custom made mixers, suitable for use in the foodstuff, dairy, and drinks industry. With their sanitary design and 316L construction, they offer great performance in the field of mixing and homogenisation. The sanitary mixers can be dimensioned for virtually any volume flow, density, viscosity, and other specific product characteristics.

Maintenance-free mixers

Predictable homogeneity

CIP cleaned quickly and effectively

Very low pressure drops

Basic features

Sanitary static mixers are suitable for the following, and many other, applications:

Foodstuff production:

- Homogenising product temperatures after a heat exchanger in a production line for sauces.

- Controlled cooling and mixing of pastas and sauces.

- Mixing tomato concentrate and water into a sauce base with the desired viscosity.

- Temperature homogenization of curd cheese after heat exchanger.

- Marbling of products.

- Pasteurising and cooling sauces.

- Homogenising the temperature of chocolate after the tempering machine.

- Mixing colouring or flavouring into chocolate, fondant or marshmallow.

- Rework melters for margarine production lines.

- Mixing sugar-based syrups and water into a desired Brix value.

- But also: Producing CIP liquid.

Drinks production:

- Decreasing product degradation in juices by mixing in nitrogen.

- Carbonising by mixing in CO2.

- Mixing juice concentrates and water.

- Mixing coffee concentrates and water.

Dairy production:

- Pre-mixer for the homogeniser.

- Pre-mixer for spray tower.

- Mixing pieces of fruit into yogurt.

- Temperature homogenisation after a heat exchanger in ice production.

- As a heat exchanger in the UHT lines for viscous medical foodstuffs.

Read more about the applications in the applications tab.

CIP cleaning

Within the foodstuffs industry, aspects like CIP cleaning, smooth and/or polished surfaces, and sanitary connectors are important for keeping germ counts as low as possible. Practice has shown that the use of PRIMIX static mixing elements and the increased speed of the product along the pipe wall, results in a significantly cleaner result after CIP cleaning, as compared to an empty pipe. The germ count afterwards is immeasurable.

The PRIMIX sanitary static mixers are easy to clean in a standard CIP or disinfection cleaning cycle. The mixers are fitted with removable mixer elements as standard, to facilitate any desired pipe inspection. This is very convenient, for example, when processing extreme viscous materials.

Retention of flavour and product characteristics – through rapid heating and cooling

Retention of flavour during pasteurisation and sterilisation processes is achieved by heating the product to a high temperature quickly, maintaining that temperature, and then cooling the product again relatively quickly. Good heat transference is essential to ensure the rapid heating and cooling. Static mixing elements ensure the continuous supply of new product to the contact surface, so that optimal heat exchange is achieved. With the sanitary static mixers, the sterilisation sections can be made significantly more compact while improving the efficiency.

Sanitary static mixers are maintenance free

What does the maintenance process look like after adding a PRIMIX static mixer to the process? To be very honest, there isn’t really a process to speak of. Simply because PRIMIX mixers require little to no maintenance at all.

Applications

Colouring and flavouring chocolate

One specific activity where the use of static mixers has proven very effective, is in mixing colouring and/or flavouring into white chocolate. In this process, a relatively small flow of colouring and/or flavouring is added to the chocolate flow. Due to the clever design, the additives are completely mixed in over the course of a very short installation length. This results in low loss of product and fewer cleaning activities. The same mixing principle is also applied to fondant or marshmallows.

Reworking margarine

In the Benelux, many margarine installations operate a PRIMIX rework mixer. In the supply line towards the packaging installation, a relatively small margarine flow is fed back, so that it is on standby. In the event of a sudden stoppage in the packaging line, the full quantity of cold margarine (6°C) is put through the rework installation and returns readily melted to the supply tank. The PRIMIX systems with hot water or steam connections have fully proven their effectiveness as rework installations in practice.

Improving temperature distribution in sauces and ice

Heat exchangers in production processes for sauces and ice have outgoing diameters of more than 50 mm. Because the products are syrupy (with high viscosity) a laminar flow profile arises in the output pipe. This means that at the centre of the pipe, the product is flowing much faster than it does at the edges. In consequence, the temperature measurements fluctuate, causing system controls to be unstable. Installing a PRIMIX sanitary static mixer will solve this issue. Due to good homogenisation, the product will have the same characteristics throughout, including consistent temperature distribution.

Making first class sauce bases

Many sauces begin their production process as a mixture of (tomato) puree concentrate which, together with water, is mixed to the desired viscosity. Whereby it is important that the mixture is perfect, otherwise the consumer will see colour and consistency variations. Today, PRIMIX static mixers are ensuring the production of first class sauce bases in many different production lines.

Pre-mix for a better homogeneity in milk

There is a lot more to modern milk production than simply milking a cow. For the right texture and consistency, milk is made smooth using a homogenisator. A PRIMIX sanitary static mixer in the supply line of the homogenisator ensures a perfect pre-mix, allowing the homogenisator to do its work even better.

Mixer design

Mixer design

At PRIMIX, there is more to the design of a sanitary static mixer. It encompasses engineering and thinking about the client’s process as a whole. Clearly determining the relevant parameters and, where necessary, daring to ask critical questions. This, with the aim of obtaining maximum performance in a mixing, heating, and/or cooling process. The intended design is calculated through completely in the PRIMIX Dynamics’ own software and then designed in SOLIDWORKS®. Read more about the PRIMIX static mixer design.

Type of mixing element

Within the sanitary static mixers, two types of mixing elements are used; the PMS screw type or helix element, and the PMX mixing element, also referred to as x-crossed type element.

PMS mixing element

PMS mixing element

-

Standard screw, helix or spiral shaped mixing element (comparable to Kenics design)

-

For static mixers with a diameter up to ±150 mm

-

Suitable for basic mixing applications, liquid and liquid gas solutions and used in heat exchangers

-

Due to the rounded sides of the element, suitable for mixing sensitive products that are prone to damage. Rounded sides are possible at the font and rear sides of the element, but also along the contour edge of the element

-

Electrolytic polishing of the element optional

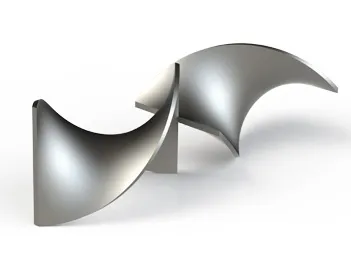

PMX mixing element

PMX mixing element

-

X-crossed type mixing element design

-

Available in many different dimensions

-

Very suitable for mixing highly viscous materials

-

Very good mixing and dispersion – for a wide range of viscosity

-

Ensures a compact design of the static mixer

-

Electrolytic polishing of the element optional

Turbulent or laminar mixing

Depending on the selected element, mixing can be divided into turbulent and laminar. In case of turbulent mixing, we mean mixing materials with a watery or slightly higher viscosity. The flow speeds are relatively high. There is a relatively high amount of radial mixing and within a short process a technically homogenous mixture is obtained.

Laminar mixing occurs with materials with a high to very high viscosity. Here, the speeds are lower, and the pressure drops high. Very little or no radial mixing occurs. The mixing effects are focused on the transition between the mixing elements. There, the two layers are forcibly mixed, creating four layers, and so on. At the menu option operating principle, you can read more about turbulent and laminar mixing.

Technical specifications

Mixer design

The PRIMIX sanitary static mixers can be manufactured from, among others, the following materials:

- Stainless Steel; 316L(1.4404) , 304L(1.4307), 321(1.4541), 316Ti (1.4571)

- PTFE (with FDA approval)

- PP Food grade

- Do you require specific materials? Please contact PRIMIX.

Surface treatment sanitary static mixers

Surface treatment sanitary static mixers

The surface of the sanitary static mixer can be finished, treated, or cleaned to specification. Generally, the casing and the internal mixing elements are supplied with a Ra < 0.8 with a Ra < 1.6 on the weld. Electrolytically polished mixing elements are available for more critical applications.

Applied flanges and connectors

Applied flanges and connectors

The sanitary static mixers can be fitted with various types of flanges and connectors. The connection will depend on the process, the pipe diameter, and the desired seals.

Connector type for sanitary mixers (more available on request)

- DIN11864 (The most sanitary connector)

- DIN11851

- Tri‐clamps

- SMS

Injectors:

Injectors

In processes where the mixing ratios are far apart or the physical material characteristics highly diverse, it is important to introduce the additive to the main flow through an injection piece. Think, for example, of a centreline injection, but injectors in clarinet shape are also interesting; the myriad possibilities can also be supplied in removable versions. The advantage of an injector is that the additive is introduced into the main flow at the ideal point before the first mixing element, making the mixing operation significantly more efficient. PRIMIX can advise you in selecting the most optimal installation for your application.

REGULATION 1935/2004

REGULATION 1935/2004

Since 27 October 2004, the European regulation is in effect for all materials that come into contact with food. For PRIMIX sanitary mixers, the regulation sets the following two main requirements:

- The materials used must be suitable for foodstuffs.

- The materials used must be traceable.

For the construction of sanitary mixers, PRIMIX uses available stainless steel sanitary components from first class manufacturers in the industry. The material stainless steel is included in Appendix 1 of the regulation (Materials with special requirements) and is generally accepted as a suitable material for foodstuffs and drinks.

We have safeguarded the traceability through EN10204 3.1 material certificates. These are recorded in the documentation bundle for the mixer.

If desired, PRIMIX will provide a compliance certificate.

Downloads

Brochure and leaflet

![]() Static mixer leaflet (English)

Static mixer leaflet (English)

![]() Staattiset sekoittimet ja lämmönvaihtimet (Suomalainen)

Staattiset sekoittimet ja lämmönvaihtimet (Suomalainen)

![]() Mieszacze statyczne i wymienniki ciepła w jednym (Polski)

Mieszacze statyczne i wymienniki ciepła w jednym (Polski)

![]() Static mixer leaflet (Taiwanese)

Static mixer leaflet (Taiwanese)

Case study data sheets

![]() #54 Cip static mixer for food homogenization

#54 Cip static mixer for food homogenization

Company

![]() Algemene verkoop- en leveringsvoorwaarden

Algemene verkoop- en leveringsvoorwaarden

Certificates

Quote request

English

English  Deutsch

Deutsch  Español

Español  Français

Français  Nederlands

Nederlands