Heat exchangers

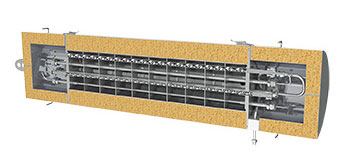

The PRIMIX spiral shaped mixer element is the basis of the heat exchangers which can be used for the inline heating and cooling of products. Because of the sophisticated construction, the PRIMIX heat exchanger takes a unique position between the current shell and tube heat exchangers. All PRIMIX heat exchangers are designed and produced to client specifications. The heat exchangers are available for the treatment of particularly high viscosity liquids.

Special manifold - mixer connection possible, resulting in true plug flow

Improved heat transfer - which results in 30 - 40% less weight

Lower pressure drop in product and on the side of the service liquid

Lower volumes and shorter residence times

Basic features

Spiral heat exchangers - faster refresh, better mixing

The design of the spiral shaped element naturally takes care of an increased heat transfer - by up to a factor 3. This is caused by the strong radial flow which causes an increase in the refresh rate on the inner walls of the process pipe.

20 to 100% more heat transfer

The applied Advanced Connection Technology (ACT), between the tube and mixing elements has a resistance to heat transfer which is equal to the resistance of the base material of the tube and element. Due to this characteristic, the surface area of each mixing element starts to behave like an additional heat-exchanging surface, which in comparison with the conventional heat exchangers results in a 20 to 100% improved heat transfer.

Static mixer heat exchanger is suitable for challenging media for example

If a standard pipe and plate heat exchanger is no longer working properly, the heat exchanger spiral elements come into the picture. Stretching and folding over the liquid layers has a positive effect on the heat transfer.

Some applications for specific industries:

Heat exchanger for viscous liquids like polymers

- Cooling a polymer to a constant temperature in the PET mill feed

- Cooling of hot melt

- Heating

- Polymer heat exchanger for mill

Heat exchanger for food

- Heating and cooling foods mildly

- Very suitable for viscous process media such as starch

Heat exchanger with an insulating sheath

The heat exchangers can be supplied optionally with an insulating sheath. The heating and/or cooling of liquids in a continuous process is a frequent operation in the chemical industry but also in the food industry.

Design

The static mixer heat exchanger

The reliable alternative to a plate heat exchanger, scraped heat exchanger, tube heat exchanger or spiral shaped tube heat exchanger.

The following types of stationary heat exchangers can be distinguished:

-

Plate heat exchanger

-

Tube heat exchanger

-

Spiral shaped tube heat exchanger

-

Static mixer heat exchanger

Usability of heat exchangers; working pressure, process temperature and viscosity

The usability of each type of heat exchanger is largely determined by the applied working pressure, the process temperature and the corresponding viscosity of the process medium. The desired capacity is achieved by choosing a certain construction size or by linking several heat exchangers in parallel.

The heat exchanger types mentioned above are placed in order of increasing usability, the heat exchanger with static mixing elements is the most usable.

Is a static mixer heat exchanger better for viscous media than a plate heat exchanger?

In applications where it is about the thermal treatment of viscous process media and processes where, for example, starch can be gelatinized, a system with a wider applicability should be chosen. . The plate heat exchanger in particular, is limited in the allowable work pressure. Pressures above about 6 bar are too high for this type, while in processes where long heating and cooling down schedules are included, the limit is reached quickly.

Better heat exchange than spiral shaped and tube heat exchanger because of the lack of tunnel effects

The applicability limits of the tube heat exchanger are mainly during the cooling of viscous process media, where - as a result of the tunnel effect occurring by fouling product - an insulating layer of product is formed on the inner wall, which can severely impede the transfer of heat. In addition, the remaining insulating product layer may have a negative effect on the quality of the final product. The spiral shaped heat exchanger has similar problems in this field of application to the tube heat exchanger. The static mixer heat exchanger has in relation to the above mentioned heat exchangers the great advantage that the temperature differences over the cross section of the flow surface are reduced, so that no insulating layer is formed and therefore this type is very useful for heat exchange in process media with a high viscosity.

More information about the application of the static mixer heat exchanger

Further applications of the static mixer heat exchangers can be found in our case studies data sheets and under the menu item industries.

It’s all-in the design

At PRIMIX design is more. It includes the engineering and thinking through the process with the client. Clearly defining the relevant parameters and where necessary daring to ask critical questions. This with the aim of obtaining maximum performance in the process . The intended design is entirely calculated in our own PRIMIX Dynamics software and afterwards is designed in SolidWorks® . The design instructions and calculations are based on strict criteria formulated in the current industrial design standards for high pressure devices. Read more about the PRIMIX design perspective.

Technical specifications

Product range static mixer heat exchangers

The PRIMIX heat exchangers can be produced, for example, from the following materials:

- (Low temperature) carbon steel and low alloyed steel, for example A106 Gr. B, A333 Gr. 6, A335 Gr. P11, etc.

- Stainless steel, e.g. 316L(1.4404), 304L(1.4306), 321(1.4541), 316Ti (1.4571), etc.

- Duplex & super duplex (1.4462)

- Exotic materials such as: alloys, Hastelloy®, titanium, nickel, Incoloy®

Surface finish heat exchangers

The surface of the static mixer heat exchanger can be finished, treated or cleaned to specification. A number of treatment techniques are:

- Staining and passivating

- Grinding & glass-grit blasting or sandblasting

- Honed finish for a perfectly smooth surface

- (Electro) polish

- Chromium plated

- Ultrasonic cleaning

Applied flanges and connectors

The static mixer heat exchanger can be provided with various types of flanges and connectors. The connection will depend on the process, the pipe diameter and the desired seal.

Connector type (more available on request)

- Bevelled weld ends ASME B16.25

- EN1092‐1 flanges: type 01, type 11, etc.

- ASME B16.5, B16.47 flanges. FF, WN RF, RTJ, etc.

- Loose flanges and sleeves for plastic construction materials

- Sanitary flanges, e.g. DIN11851, bio-connect, tri‐clamps, aseptic DIN11864, SMS

- Thread ends, e.g. union joints, Swagelok®

Options and implementations of the heat exchanger

- Demountable

- Honed inflow sides

- Polished

Downloads

Brochure and leaflet

![]() Static mixer leaflet (English)

Static mixer leaflet (English)

![]() Staattiset sekoittimet ja lämmönvaihtimet (Suomalainen)

Staattiset sekoittimet ja lämmönvaihtimet (Suomalainen)

![]() Mieszacze statyczne i wymienniki ciepła w jednym (Polski)

Mieszacze statyczne i wymienniki ciepła w jednym (Polski)

![]() Static mixer leaflet (Taiwanese)

Static mixer leaflet (Taiwanese)

Certificates

Quote request

English

English  Deutsch

Deutsch  Español

Español  Français

Français  Nederlands

Nederlands