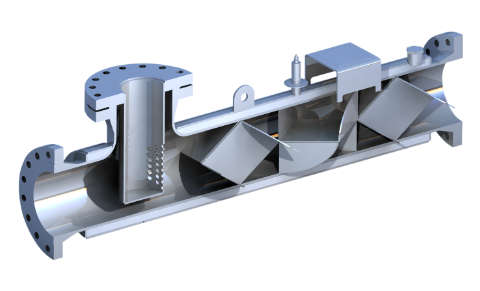

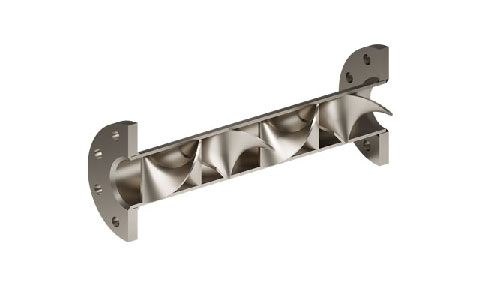

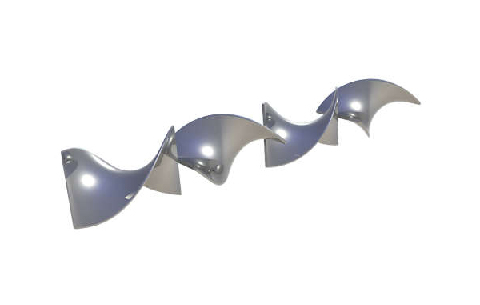

PRIMIX Static mixer

The variations available in the static mixers that PRIMIX manufactures are virtually endless, such as the diameter, shape and number of mixer elements, fixing methods inside the elements' housing, the construction material, the connections, and a possibly integrated injector etc.. Therefore PRIMIX also builds static mixers to client specifications. Exceptions are the static mixers from our Quick Delivery System (QDS) Programme, that can often be supplied within a few days.

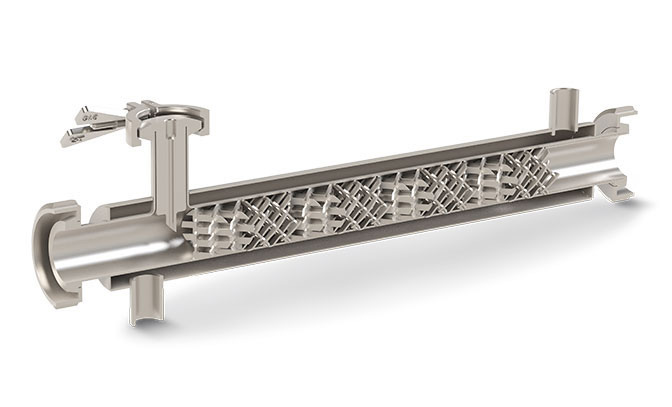

Static mixer heat exchanger

The PRIMIX static mixer enables you, next to controlled mixing, to improve the heat transfer within heat exchanging processes. The use of these mixer elements in tube heat exchangers provides, especially in applications where viscous liquids need to be cooled, a significant improvement to the heat transfer, which means a more compact heat exchanger can be constructed. For applications where a short residence time and a minimal residence time spread play a role, compact design has big advantages.

English

English  Deutsch

Deutsch  Español

Español  Français

Français  Nederlands

Nederlands